Powder Coating

For over 70 years, Associated Finishing has been a leader in the industry, delivering durable and environmentally friendly powder coatings for a wide range of industries, from agriculture to aerospace.

With state-of-the-art facilities in Mankato, Litchfield, & Blooming Prairie, Minnesota, our skilled technicians ensure every project meets your exact specifications.

What is Powder Coating?

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and applied to a grounded surface. Once coated, parts are cured in an oven, where the powder melts and fuses into a durable finish. This process offers superior resistance to chipping, scratching, and corrosion, while providing a range of colors and textures.

Benefits of Powder Coating

Durability

Long-lasting protection against wear and environmental factors.

Eco-Friendly

Minimal waste and low VOC emissions make this process environmentally responsible.

Efficiency

Robotic application systems, in-line part washing, and conveyor powder coating lines ensure precision and repeatability for high-volume projects.

Versatile Finishes

Hundreds of color and texture options, including clear, metallic, and high-temperature coatings.

Applications of Powder Coating

Automotive

High-performance coatings for parts that endure wear and tear.

Industrial

Protective finishes for machinery and tools.

Consumer Goods

Decorative and functional coatings for appliances, furniture, and more.

Specialized Powder Coating Capabilities

Custom Masking

Engineering expertise ensures precision and cost savings.

Specialty Coatings

Zinc-rich primers, U.V. protection, and high-temperature finishes.

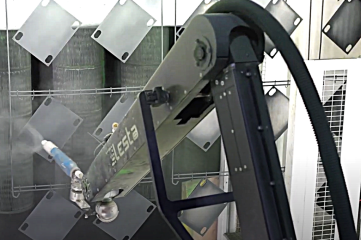

Robotic Application

Self-training systems for unparalleled consistency and efficiency.

Our Powder Coating Process

Associated Finishing’s powder coating process is designed for precision and quality:

Surface Preparation

Thorough cleaning and pretreatment ensure optimal adhesion.

Masking

Custom masking solutions protect sensitive areas during coating.

Application

Robotic and manual systems apply the powder evenly.

Curing

Coated parts are heat-cured for a durable, uniform finish.

Packaging

Parts are packaged to make it to the final destination without damage.

Inspection

Every part undergoes a 100% visual inspection to ensure perfection.

Why Choose Associated Finishing as Your Powder coaters?

Advanced Technology

Robotic powder coating systems for consistent quality.

ISO 9001:2015 Certification

Rigorous quality standards for every project.

Comprehensive Services

From zinc-rich primers to U.V.-protected finishes.

Large-Scale Capabilities

Handling parts up to 40 feet in length and batch sizes up to 5,000 pieces.

Frequently Asked Questions About Powder Coating

Contact Expert Powder Coaters Today

Associated Finishing is here to meet your powder coating needs with precision, reliability, and unmatched quality. Contact us today to request a quote or learn more about our comprehensive services.