Paint Stripping

Paint Stripping

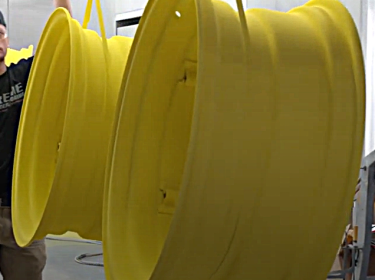

Paint stripping is a reliable and cost-effective method for removing coatings from metal and other substrates without damaging the underlying material. At Associated Finishing, we provide high-quality paint stripping services to help manufacturers reclaim parts, clean production equipment, and prepare surfaces for refinishing.

Associated Finishing’s stripping techniques efficiently remove old coatings, reducing downtime while maintaining product integrity.

Our team understands the complexities of coating removal and surface restoration and can determine the best solution for your project. Whether you’re removing powder coatings, liquid finishes, epoxy, nylon, or E-coating, our paint stripping process ensures clean, uniform results that meet industry standards.

Methods of Paint Stripping

Associated Finishing offers three methods of stripping, enabling us to select the most suitable approach based on coating type, part geometry, and material sensitivity. This ensures optimal results while preserving the integrity of even the most delicate components.

| Method | Effectiveness | Best Used For |

|---|---|---|

| Chemical Stripping | High | Preserving substrate integrity while removing coatings |

| Burn Off Oven | High | Bulk removal of coatings on steel substrates from racks, fixtures, and parts |

| Abrasive Blasting | Medium | Surface etching and heavy-duty coating removal |

Chemical stripping involves using specialized solutions to break down and remove coatings from a surface. Chemical stripping eliminates paint, powder coats, and other organic finishes without damaging the base material.

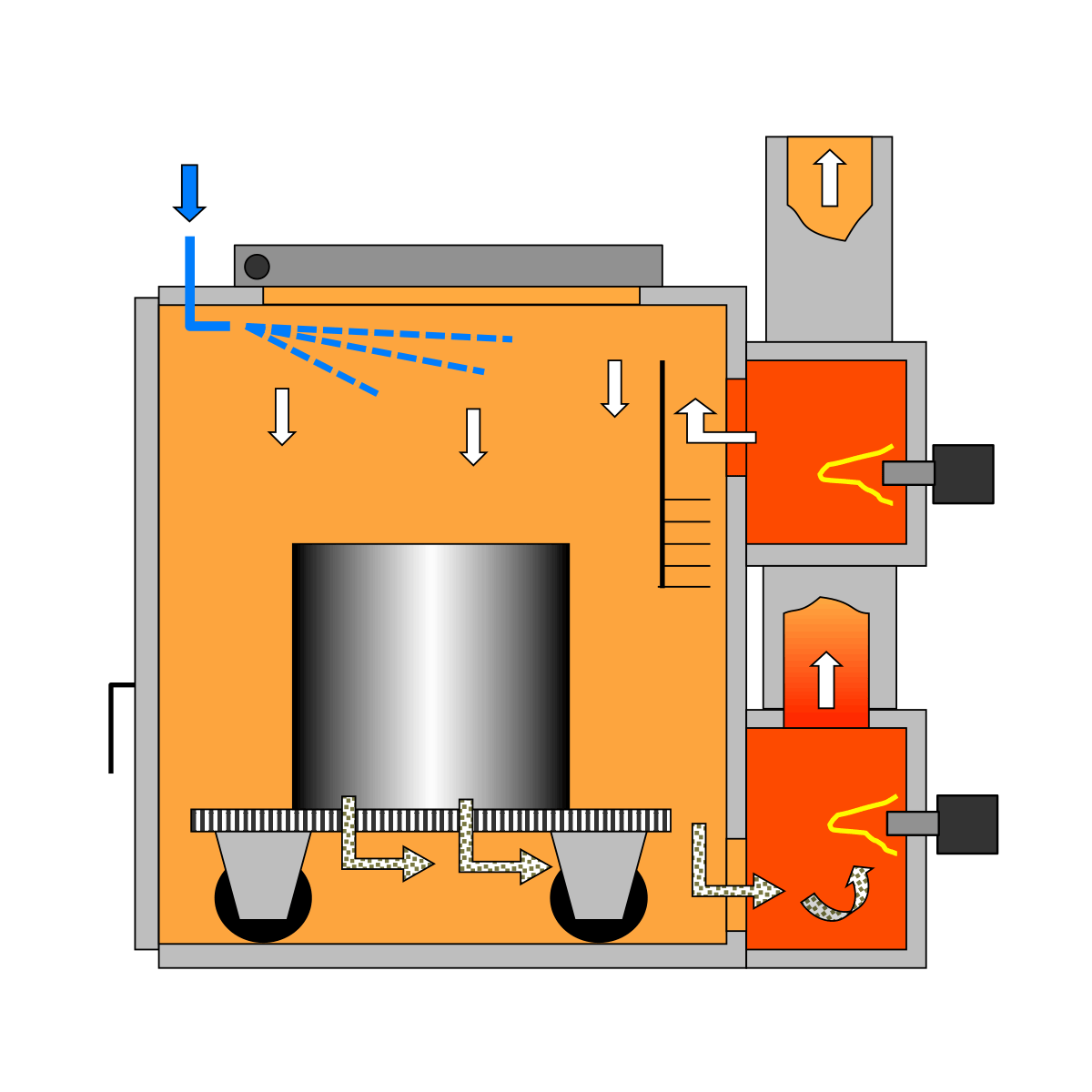

Using a burn-off oven to remove paint, also known as thermal stripping, involves exposing metal surfaces to high temperatures in an oven to break down and remove paint, coatings, or other contaminants.

Abrasive blasting, also known as media blasting or sandblasting, is the process of propelling an abrasive material at high velocity against a surface to remove contaminants, old coatings, rust, and oxidation.

Advantages of Each Method

All three methods offer safe and effective coating removal, but each has its advantages for specific jobs.

Chemical Stripping

- Particularly effective for delicate components and high-precision applications.

- Reduces the risk of damage to especially thin or aluminum substrates

- Effective on complex shapes because it penetrates hard-to-reach areas.

- Minimized dust and airborne particles.

- The preferred method when protecting the base material is a priority.

- Ideal for parts requiring precise tolerances and smooth surface finishes.

Burn-Off Oven

- Highly Effective for Thick Coatings & easily removes multiple layers of paint.

- Works well for large components, including automotive parts and large metal structures.

- Cost-effective for bulk processing: burn-off ovens can process large batches of parts simultaneously

- Environmentally friendly because it does not require chemicals.

Abrasive Blasting

- Promotes adhesion for the next coat of paint while removing the existing coating

- Removes rust and corrosion in addition to paint.

- Can be used on a wide range of substrates including steel, aluminum, and stainless steel.

Each stripping method efficiently removes a wide range of coatings, including:

- Epoxy and nylon coatings

- Powder coatings and liquid finishes

- CARC coatings for military applications

- E-coating and high-performance industrial coatings

Cost-Effective Reclamation and Reuse

Paint stripping enables you to restore metal parts with worn-out finishes, thereby reducing replacement costs. Reclaiming parts also minimizes waste, disposal costs, and environmental impact.

Surface Preparation for Recoating

Proper surface preparation is crucial for achieving coating adhesion and durability. Chemical stripping ensures a clean, contaminant-free surface, making it easier to apply:

- Powder coating

- Liquid coatings

- Anodizing and plating

Chemical stripping provides a clean foundation for superior adhesion and long-lasting coatings in industries that require high-performance finishes, such as aerospace, automotive, and industrial manufacturing.

Paint stripping is widely used across multiple industries, including:

Complete Finishing Solutions from Associated Finishing

In addition to paint stripping, Associated Finishing offers a full range of industrial finishing services to support manufacturing and production needs. Options include:

With multiple facilities and a history of excellence, we provide end-to-end finishing solutions that help manufacturers optimize their processes and extend the life of their products.

Request a Quote for Paint Stripping

If you need a safe, efficient coating removal solution, Associated Finishing is ready to assist. Our stripping services ensure thorough, damage-free surface restoration, preparing your parts for their next application.

Contact us today to discuss your project or request a quote.

Learn more about our complete range of finishing services.